Enhance Your Home’s Insulation with Spray Foam Insulation Kirksville MO for Long-Term Benefits.

Enhance Your Home’s Insulation with Spray Foam Insulation Kirksville MO for Long-Term Benefits.

Blog Article

Seamless Spray Foam Insulation to Minimize Power Expenses

The implementation of seamless spray foam insulation provides an engaging opportunity for residential or commercial property owners looking for to enhance energy effectiveness and substantially lower power costs. As we check out the details of this insulation technique, its wider effects for power preservation and residential or commercial property worth improvement warrant more detailed examination.

What Is Spray Foam Insulation?

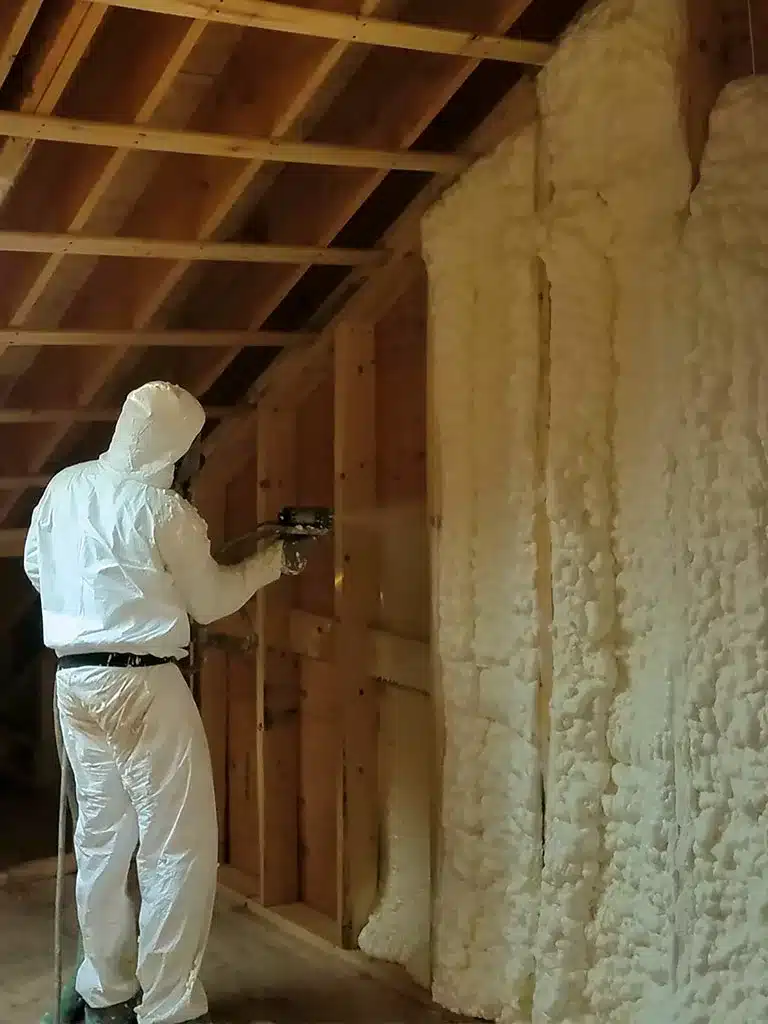

Spray foam insulation is a very reliable and functional insulation material that has gotten appeal in both domestic and business building. This cutting-edge insulation solution is composed of a mixture of isocyanate and polyol material, which, when combined, expands swiftly to produce a strong foam obstacle. The one-of-a-kind homes of spray foam enable it to fill gaps and gaps in different structures, offering exceptional air sealing and thermal resistance contrasted to typical insulation techniques.

There are two key kinds of spray foam insulation: open-cell and closed-cell. Open-cell foam is lighter and less dense, supplying superb noise absorption and flexibility, making it ideal for indoor applications. On the other hand, closed-cell foam is denser and much more rigid, providing added wetness resistance and structural integrity, which is specifically beneficial for outside applications.

The application process usually includes professional tools to make certain precise setup, allowing the foam to stick safely to surfaces and broaden to fill rooms effortlessly. Because of this, spray foam insulation not just improves energy performance yet likewise adds to preserving a comfortable interior environment by regulating temperature level and decreasing air infiltration.

Benefits of Smooth Application

Moreover, the smooth nature of this application permits much better attachment to different substratums, consisting of uneven surfaces. This makes sure that the insulation continues to be intact gradually, lowering the risk of working out or wear and tear, which can endanger efficiency. Additionally, the smooth application aids stop dampness invasion, which is critical in staying clear of mold growth and structural damages.

One more significant benefit is the rate of application. Smooth spray foam can be installed swiftly, typically in a solitary day, which decreases labor costs and task timelines. This performance not just benefits contractors but additionally residential or commercial property proprietors seeking to lessen disruptions.

Last but not least, the flexibility of spray foam insulation enables it to adjust to intricate architectural designs, ensuring detailed insurance coverage in hard-to-reach areas. This flexibility further enhances the general efficiency of the insulation system, bring about an extra comfy interior setting.

Power Performance and Price Financial Savings

The smooth application of spray foam insulation dramatically adds to power effectiveness and cost financial savings for building owners. This cutting-edge insulation service creates a reliable air obstacle that lessens air leaks, minimizing the demand on heating and cooling down systems. By preserving a constant indoor temperature, spray foam insulation ensures that buildings continue to be comfortable year-round, leading to reduced energy usage.

Buying spray foam insulation can translate right into significant long-lasting financial savings. Studies have actually revealed that buildings insulated with spray foam can experience power cost reductions of approximately 50%. This is particularly beneficial in areas with severe weather condition problems, where power expenses can be too high. The longevity and durability of spray foam insulation imply that building owners can expect to enjoy these cost savings over a prolonged period without the requirement for regular substitutes.

Along with route power expense financial savings, the improved power performance of a building can increase its general market price. Possible buyers and occupants frequently prioritize energy-efficient properties, making seamless spray foam insulation a calculated financial see here investment for those looking to maximize their roi in the property market.

Installation Process Introduction

Comprehending the setup procedure of seamless spray foam insulation is important for guaranteeing optimal performance and long life. The installment commonly starts with a complete analysis of the area to be shielded, identifying any kind of existing air leaks or dampness problems that need attending to (spray foam insulation columbia mo). Appropriate prep work is necessary; this may entail cleaning surface areas, eliminating any particles, and making sure that the area is free from impurities

Next, professionals will certainly put on protective equipment and set up the spray foam equipment, that includes a warmed spray gun and two-component foam materials. The foam components are mixed and heated to achieve the optimal consistency for application.

During the spraying process, the foam broadens quickly upon application, filling voids and producing a smooth obstacle. It is necessary to apply the foam evenly and at the proper thickness to satisfy building ordinance and power performance criteria.

After application, the foam treatments swiftly, normally within a couple of hours, enabling a speedy go back to typical tasks. Any kind of excess foam is trimmed to guarantee a smooth surface, and the location is evaluated for quality assurance. This precise procedure is crucial to maximizing the benefits of smooth spray foam insulation.

Upkeep and Long Life

Preserving seamless spray foam insulation is essential for ensuring its long-lasting performance and efficiency. This kind of insulation is made to last for decades, yet routine upkeep can maximize its life-span and energy-saving abilities.

First, it is very important to regularly check the insulation for next any type of indicators of damages, such as fractures or spaces. If any kind of concerns are spotted, prompt repair services need to be made to prevent air leaks and wetness seepage, which can compromise the insulation's honesty.

In addition, keeping appropriate ventilation in the building is essential, as extreme humidity can cause mold and mildew growth, adversely affecting the insulation's performance. Consistently cleansing gutters and ensuring drain systems are operating effectively will additionally assist reduce water damage risks.

Furthermore, staying clear of extreme weight or pressure on the protected areas is essential (spray foam insulation columbia mo). Hefty objects can press the foam, lowering its protecting buildings

Final Thought

In final thought, seamless spray foam insulation becomes a highly reliable option for enhancing power effectiveness in both residential and business settings. By forming a constant obstacle, it dramatically minimizes air leakage, resulting in considerable energy price financial savings. The quick installment process additionally highlights its financial benefits, while visit our website its durability adds to long-lasting building worth enhancement. Overall, smooth spray foam insulation stands for a critical investment that advertises comfort and sustainability in contemporary structure practices.

Report this page